The Hunt WTec range of D-type watertube boilers has been designed with a primary focus on being able to achieve the most energy efficient product range possible, and incorporates the most up-to-date technology available

The design includes both a Flooded Tube Economiser (FTE) and the more traditional Flue Based Economiser (FBE), that work sympathetically together to ensure optimal latent heat recovery is achieved.

They are manufactured in our Hunt Boilers' Queensland workshops and our International facilities, configured for Unattended operation up to 10 MW, and limited attendance operation for the balance of the product range that extends to 20 MW in standard form.

The WTec range is provided with standard design pressures of 1200 kPa or 1800 kPa, and is suitable for a wide range of fuels including Natural Gas, LPG, CSG, Bio Gas, Oil and various dual fuel options.

The key features of the product range include:

Conservative heat transfer rates with over sized heating services

Incorporating both FTE and FBE technology for best possible efficiency outcomes

Large combustion chamber which is completely gas tight

Multiple pass gas circulation

Large steam and water drums to increase accumulation to better meet fluctuating demands

Manways fitted to water and steam drums to enable effective access for servicing

No welds required on tube fin tips minimising fatigue in this area

Fully packaged complete with feed water pumps

Water level controls fitted directly into boiler drum

High class finish and appearance

Higher pressure models also available

Hunt WT6000e 6MW standard gas fired steam boiler

Hunt WT8000ec 8MW standard gas fired steam boiler, as installed

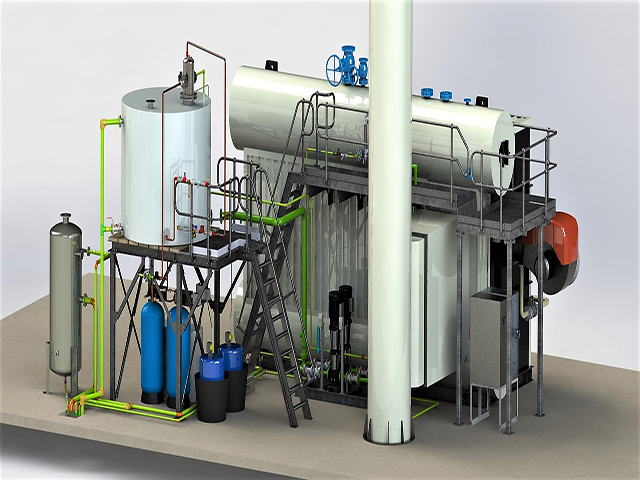

Hunt WT6000ec 6MW 3D model of a typical complete installation

Hunt WT8000e 6MW standard gas fired steam boiler

All Hunt Boilers WTec series are manufactured using the latest NC equipment

WTec total of three flue gas passes, with final pass through FTE and FBE extended fin tube