Hunt Boilers are conscious of providing products that reduce the energy required to produce steam

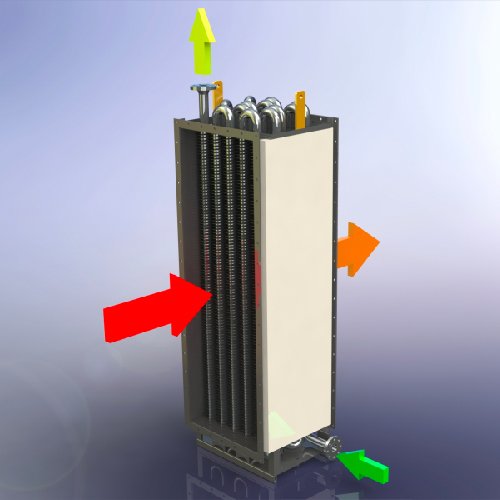

The fitting of a flue gas economiser will typically recover between 3% and 6% of normally wasted energy, depending on the feed water temperature. They can be supplied as part of original equipment orders, or retrofitted to just about any steam boiler installation.

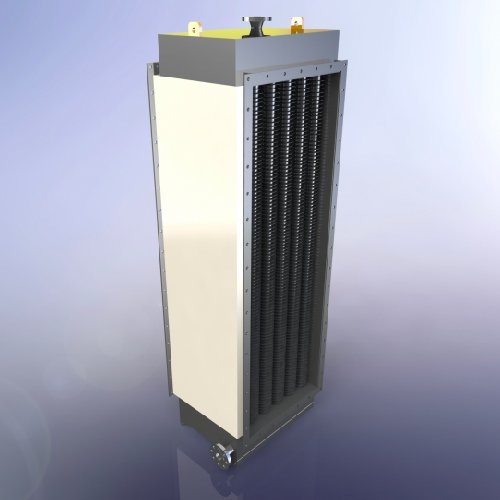

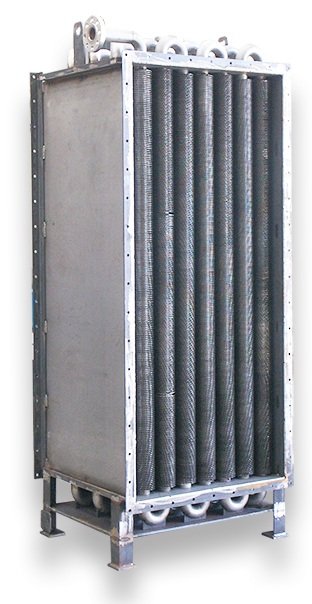

Our standard economisers are configured as a vertical tube arrangement manufactured from corrosion resistant steel with extended fin tube.

Our enclosures are gas tight with a high temperature insulated cover. They are designed so that they will operate at 100% of their designed duty without bypassing any flue gas or feedwater.

The key features of the product range include:

Conservative heat transfer rates with over sized heating services

Incorporating both FTE and FBE technology for best possible efficiency outcomes

Large combustion chamber which is completely gas tight

Multiple pass gas circulation

Large steam and water drums to increase accumulation to better meet fluctuating demands

Manways fitted to water and steam drums to enable effective access for servicing

No welds required on tube fin tips minimising fatigue in this area

Fully packaged complete with feed water pumps

Water level controls fitted directly into boiler drum

High class finish and appearance

Higher pressure models also available