PWS Hunt Boilers offer a range of advanced tray type deaerators in capacities from 4,000 to 400,000 kilograms per hour of boiler feed water

They incorporate world leading technology, provided through an agreement with the Bryan Steam Corporation in the U.S.A., which together with many other features allows for the complete deaeration process to occur within a stainless steel chamber.

The vessels are manufactured to Australian pressure vessel standards including AS1210, AS4458, AS4343 and AS3920 and are suitable for installation and operation throughout Australia, and are available in vertical, horizontal or other combinations to suit a wide range of applications.

The tray assemblies are constructed from 316L stainless steel and are designed to offer maximum residence time, ensuring complete deaeration even during wide load swings.

All external surfaces of the vessels are lagged with 50mm thick insulation over which cladding is fitted for surface protection.

The key features of the product range include:

Oxygen removal to .005 cc/L (cubic centimetres per litre)

Removal of Carbon Dioxide (CO2) to 0% measurable

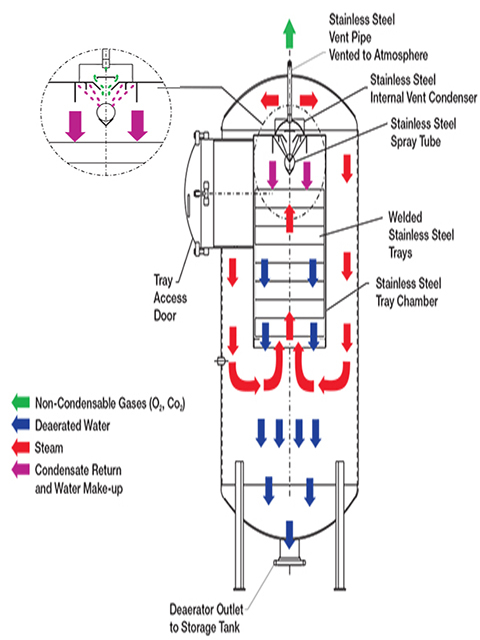

Deaeration process performed by multi-level trays housed within a tray chamber, all manufactured from 316L stainless steel

Reduced chemical costs and system corrosion

Pre-heated boiler feed water for improved boiler efficiency

Easy access to trays and storage tank for inspection and maintenance

Internal direct contact vent condenser for minimum steam loss

Two stage deaeration for maximum efficiency

Standard design pressure of 365 kPa

Other sizes, configurations and pressure ranges also available

FDH series 27 MW Deaerator installed at Coal Seam Gas site, NW Queensland

316L material is used for trays and tray box to resist corrossion

Deaerator storage vessel to suit 225MW (359 tph) for super heated steam

FDH series 30 MW Deaerator installed at Coal Seam Gas site, NW Queensland

Diagram showing the standard flow of steam, water and venting

FDV series 20 MW Deaerator installed at Pulp Processing Plant, Melbourne

FDH series 225 MW Deaerator storage vessel - painted

FDH series 225 MW Deaerator storage vessel - Insulated prior to installation

FDH series 225 MW Deaerator deaeration vessel - Insulated prior to installation